Blade Design Logic

Blade Steels & Design Details

Blade Steel Today . . .

- All high carbon knife blade steels are forged steel.

- HRC ratings of 56 to 59 are considered ideal for kitchen knife blades.

- These blades are: durable, easy to sharpen, flexible, forgiving, able to endure daily use & most accidental encounters.

- Traditional knife steels are evolving ... yielding significant durability benefits & currently remain competitive.

- Performance data for traditional knife steels found online today is often outdated.

- Modern Super Steels of 60-62+ HRC are emerging providing more durability,

though they remain difficult to sharpen.

Knife Steel Info . . .

- Producing high-carbon stainless steels ideal for knife blades is a lengthy forging process, which can take months.

- Final optimization processes include heat treating & cryo-quenching to form the most desirable steel microstructures.

- Ideal blade steels selections depend upon the end users needs.

- We use steels designed & optimized for individual knife style & their intended use including . . .

- High Carbon Forged Stainless Steels,

Multilayer... High Carbon Forged

Stainless Steel & Super Steels.

- We are always open to considering other high-quality knife steels.

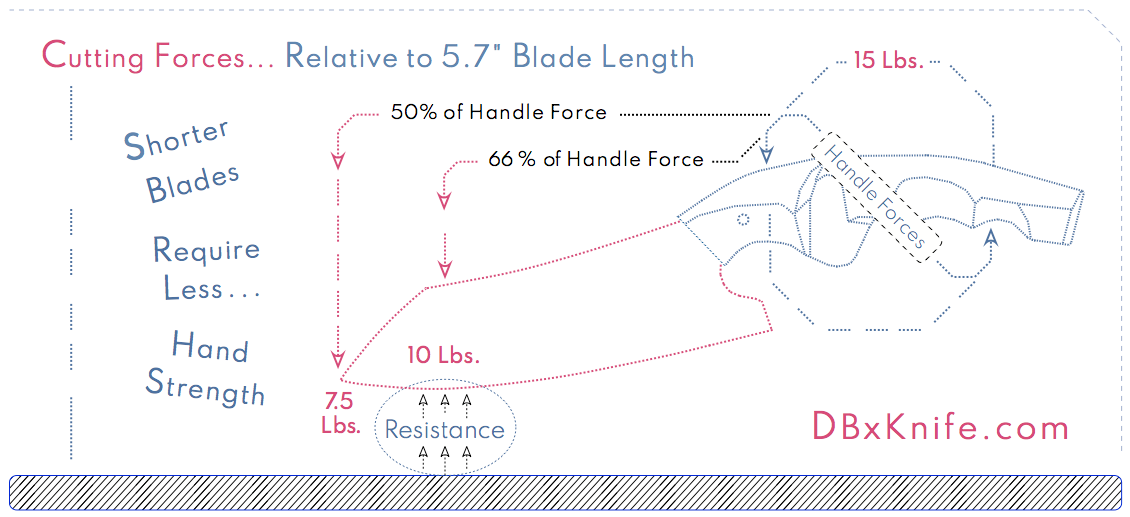

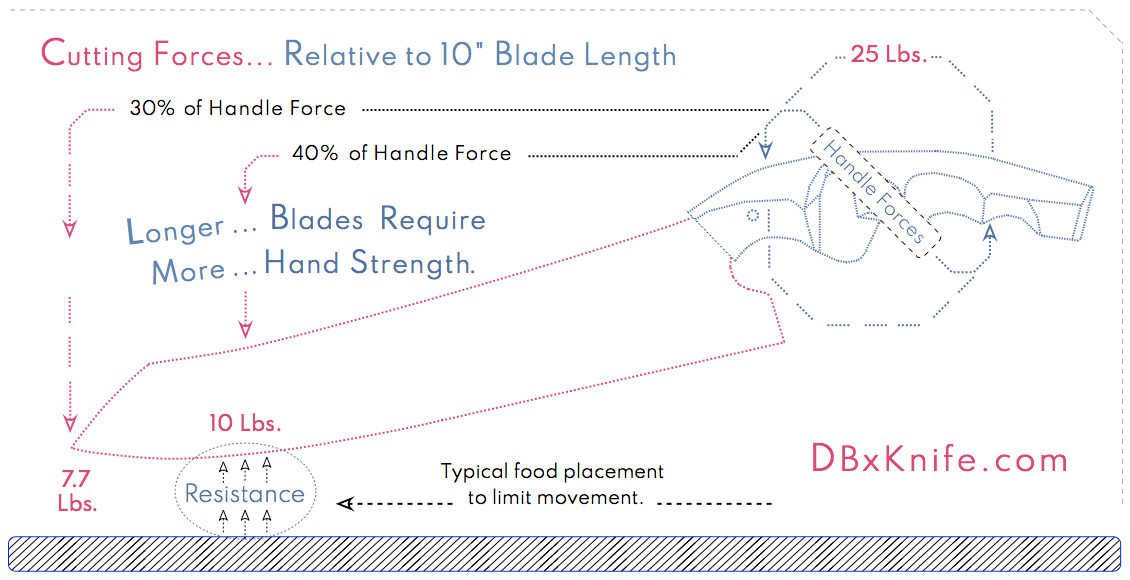

Blade Length - Selection

Relative Power Requirements

Kitchen Knife Ergonomics

Blade - Style

& Performance

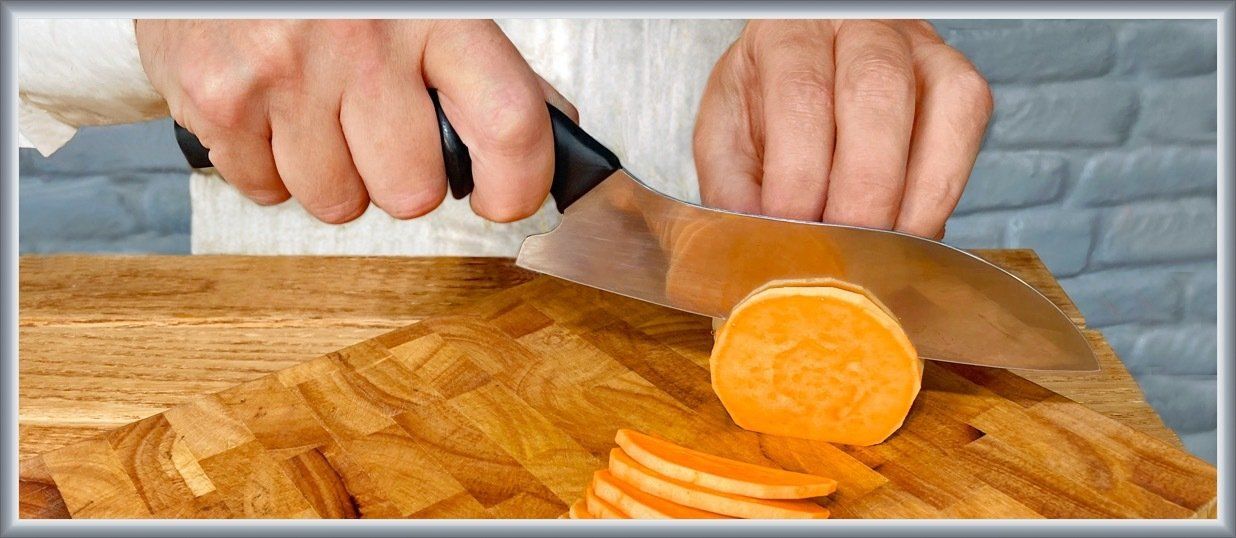

- The real magic in culinary knife blade performance is in thinner blade profiles.

- Thin, precision ground blades, require challenging & time-consuming machining processes.

- These challenges increase the costs of creating knife blades with outstanding performance.

- Thin/lightweight knives, provide more user feedback, yielding optimized knife handling skills & cutting techniques.

- The enhanced ergonomics of thinner/ lighter knife blades are apparent, especially when used for extended periods of time.

- Thicker/heavier culinary blades resist damage, though unable to match the performance of thinner blades for most culinary tasks.

- Thicker knife blades require more power input,

increasing a user's risk of losing control & cutting themselves.

Cutting Edge ...

Performance ...

- The ultimate cutting edge: is unique to the end user, their knife handling skills, the knife blade steel & the foods they cut.

- All knives get dull... the best knives to own are the ones you can easily sharpen.

- Learning to sharpen thin, flat-ground knives with inexpensive diamond sharpeners, is quick & easy.

- Low abrasive speed/pressure sharpening methods yield twice the durability of knives sharpened w/high abrasive speed/pressure.

- Sharpen & conduct your own real-world testing for edge performance/ durability.

- Synthetic & standardized test methods are often irrelevant to your use case scenario.

- Remember...

you will be the first tool to wear out;

sharpen your knives,

preserve your health & energy.

Culinary Knife - Designs

Blade Height (Width)...

Increased Blade Height:

- Provides finger/knuckle to cutting board clearance.

- Yields more available blade surface area for the guiding fingers.

- Provide clearance to increase handle angle, reducing wrist angle & stress.

Added Functionality/Uses:

- Crushing ginger & garlic cloves to activate enzymes for health benefits.

- Ease transfer of sliced & diced foods from cutting boards to pots, pans & bowls.

Limited Blade Height:

- Enhances directional control & stability.

- Reduces blade surface area & related slicing friction.

- Improves food carving attributes.

Blade Profiles & Styles ...

- Thinner/lighter blades are easier to push through harder, high-density foods.

- Taller/wider blades ... yield visual cues for consistent/accurate slicing & dicing... while substantially improving user safety, comfort & control.

- Shorter length blades enhance user control & cutting accuracy.

- Double bevel blade profiles reduce cutting force by 20%; compared to conventional convex ground blades.

- Thicker/heavier blades increase chopping power & reduce flex, but incur more unintentional cutting edge damage.

- Knife styles with the lower portion of blade exposed

( half or no bolsters ) are easier to

re-profile, thin & sharpen.

Blade Spine & Finger Reliefs

- Blade spines rounded & contoured minimize handling pressure points.

- Thinner blades ( 1.0 ~ 1.7 mm ) reduce cutting power requirements significantly in high-density foods.

- Finger reliefs

allow for

hand &

finger positions closer to knife point & cutting edge,

improving

comfort & control.

Granton Blades . . .

- These blade reliefs are designed to prevent food from sticking to the blade.

- According to knife testers, most Granton blade designs do not function as intended.

- Improve food release

...

Wet the blade with a low-viscosity fluid like water & select a thinner blade.

Knife Blade Geometry

Behind the Cutting Edge

DBx Thin - 0.005”~0.008”

Note . . .

- Cutting edges - 17º to 34º often yield imperceptible changes in cutting force on very thin blades.

Pros . . .

- Lowest cutting force in high-density foods.

- Perceptibly half the cutting force of standard thin kitchen cutlery in high-density foods.

- Lightweight blades provide excellent user feedback.

- Simple/easy to sharpen.

Cons . . .

- Ability to withstand abuse is very limited.

- Not compatible with carbide pull-through sharpeners.

- Knife tips are easily damaged.

- Not a substitute for a pry bar.

Std. Thick - 0.012”~0.016”

Note . . .

- Low-angle cutting edges are often used on thicker blades to mitigate higher cutting force requirements.

Pros . . .

- Ability to withstand most accidental encounters.

- Good performance on delicate & low-density foods.

- Knife tips are less likely to bend/break when dropped, especially on softer surfaces.

Cons . . .

- Low-angle cutting edges are easy to roll over, rapidly dulling the knife.

- Higher cutting forces, especially in high-density foods.

- Perceptibly twice the cutting force of standard thin kitchen cutlery in high-density foods.

Std. Thin - 0.008”~0.012”

Pros . . .

- Low cutting force in high-density foods.

- Perceptibly half the cutting force of standard thicker kitchen cutlery in high-density foods.

- Easy to sharpen with quality abrasives.

- Lightweight blades provide good user feedback.

Cons . . .

- Ability to withstand abuse is somewhat limited.

- Knife tips may bend when dropped, especially on hard surfaces.

- Not a substitute for a pry bar.

Tough Thick 0.016”~0.020+”

Note . . .

- Prevalent in thicker butcher knife designs w/stronger 32º per-side cutting edges.

Pros . . .

- Tough/durable with an ability to endure most accidental encounters.

- These designs provide the durability to cut through small to medium-sized bones.

Cons . . .

- Increased cutting forces are required, especially when cutting high-density foods.

- More metal to remove;

therefore,

more difficult to sharpen.

Blades & Cutting Edge Profiles

Blade Tip Designs . . .

- Western/Euro Chef Knives ... with thicker, low-profile points work well...

- Maneuvering between bones

in large cuts of meat &

general food preparation.

- The trade-off is low profile; finer knife points are less durable when accidentally dropped.

- Santoku Knives - a newer style, intended to be a more user friendly cook's /chef's prep-knife.

- Designed for... slicing, dicing &

chopping of . . .

meats, fruits & vegetables.

- Larger tip/point designs increase stability & durability

on thinner knife blades.

Ideas to Consider . . .

- Your height... more precisely, how far your elbow is above the cutting surface.

Helps determine appropriate ...

- Blade curvature in the forward

section of the cutting edge.

- Handle geometry relative to

the knife cutting edge.

Chef - Knives

Western/European

- Blade geometry features more cutting edge curvature . . .

which generally works well on a

cutting board for taller

users ( 5'10"+).

Santoku- Asian Styled Knives

- Versatile ergonomic cooks/chefs

Prep-Knife for smaller users.

( 5'10” or less)

- Reduced cutting-edge curvature.

Cutting... Edges & Boards

Flat Profile Cutting Edge

- Flat cutting-edge profiles work well under ideal circumstances with extremely flat cutting boards.

- Improperly... sharpened, steeled, or honed flat cutting edges quickly turn into concave cutting edges.

-

Concaved

knife cutting edges &/or

cutting

boards yield

partially

sliced/cut foods.

- A flat cutting edge’s contact with a cutting board is relatively abrupt, sending a shock wave up through the hand & arm.

- Personally,

I find this uncomfortable &

annoying.

Curved Cutting Edges

- Edge profiles with slight or significant curvature are more practical,

forgiving & comfortable for daily use.

- Convex/curved cutting edges perform well on slightly worn/concave cutting boards.

- They are more forgiving in terms of imperfect sharpening.

- Reduced contact areas require less pressure to cut into or through high-density foods.

- These cutting edge profiles lend themselves to rocker-style slicing & dicing methods.

Cutting Edge Destruction

Pull-Through ...

Carbide Sharpeners

- These sharpeners rip apart the structural bonds in high-carbon steels.

- This destabilizes/cracks the metal in & behind the cutting edges on all knives.

- Repairs are time consuming & costly

shorting the useful life of the knife.

- The resulting con-caved cutting edge profiles will deteriorate knife performance rapidly.

- Sharpen thin high-carbon knife steels on a flat diamond or stone abrasive surface.