Knife Sharpening, Tips & Info.

Realistic, Simple & Practical

“Edge geometry is actually more important than steel & more important than heat treatment”

“Dr Larin Thomas” Metallurgist ~ ( Steel Scientist )

Sharpen, Basic Concepts ...

- Thinner blades, with smaller cutting edges, are easier to sharpen.

- Thin,

full flat-ground knives

with

double bevel cutting edges, don't require precision sharpening

to perform well.

- Sharpen the quick & easy way... with a couple of simple edge leading strokes on an inexpensive diamond plate.

- Test your knife on the foods you are cutting. If it cuts well, you are done. If not, try a few more strokes.

- Sharpening once every 5 to 6 weeks is considered an average interval for well-used culinary knives.

- Personal use ... thin, flat-ground knives may need to be thinned once every ten years to revive performance levels.

- All knives get dull. The best knife to own is one you can easily sharpen.

Practical Sharpening Info

- Kitchen knives, up to 59-HRC, can be sharpened quickly with inexpensive dual grit diamond plates.

- Avoid over sharpening to preserve the thinnest portion of the knife blade & it's cutting performance.

- Culinary knives do not need to be perfectly sharpened/apexed to perform well.

- If you are willing to ignore damage in 0.01% of the cutting edge, you can easily quadruple the practical life of a knife.

- Generally, these imperfections don’t affect the perceived performance of a culinary knife.

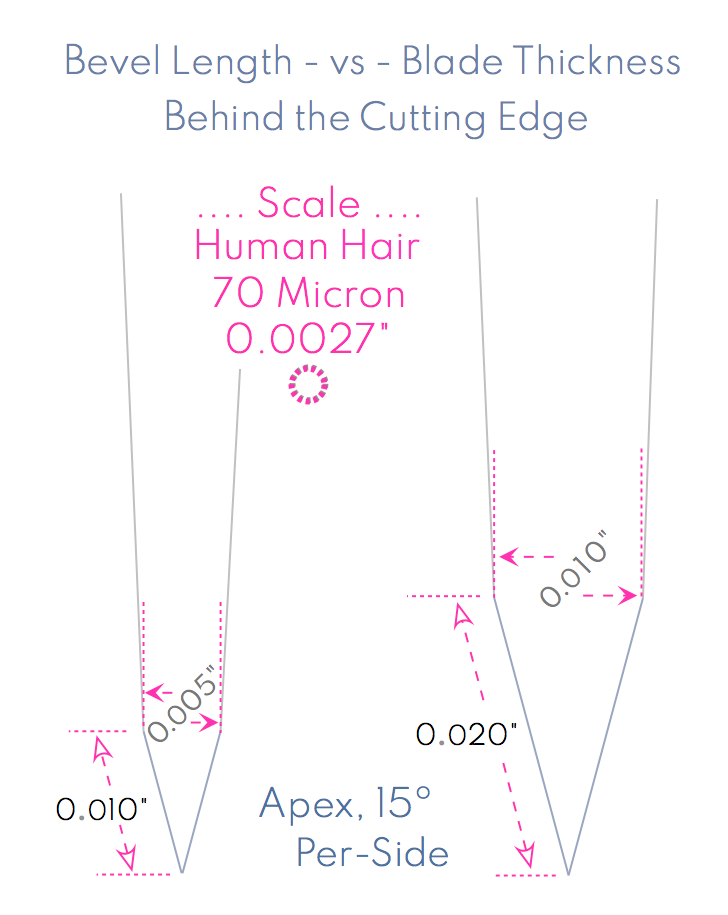

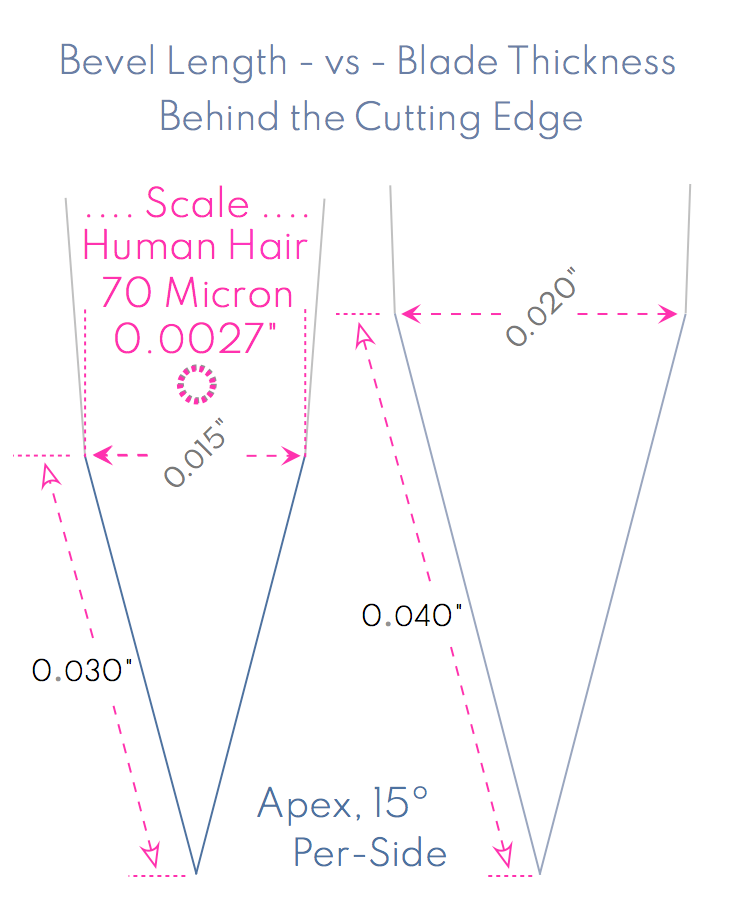

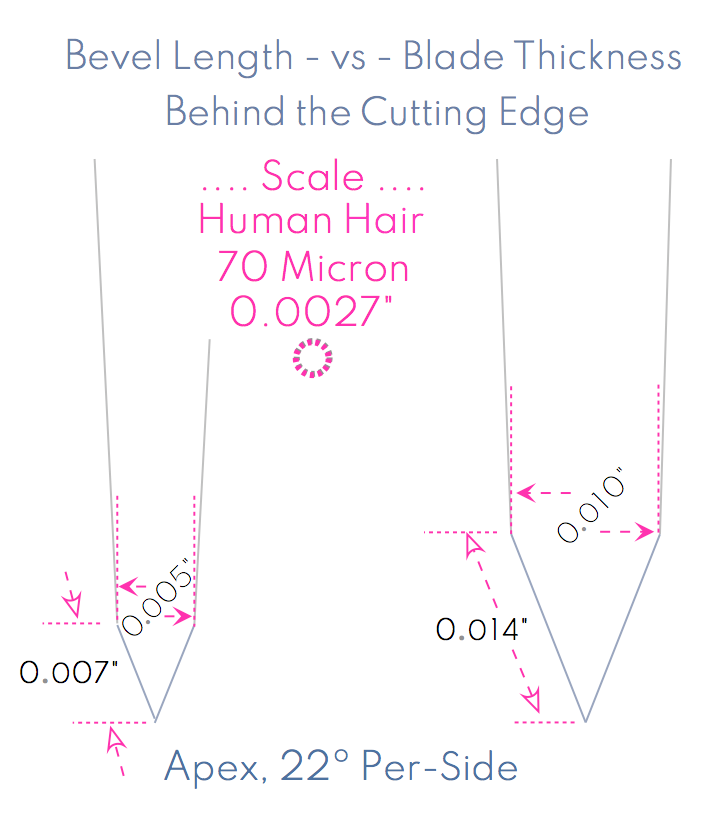

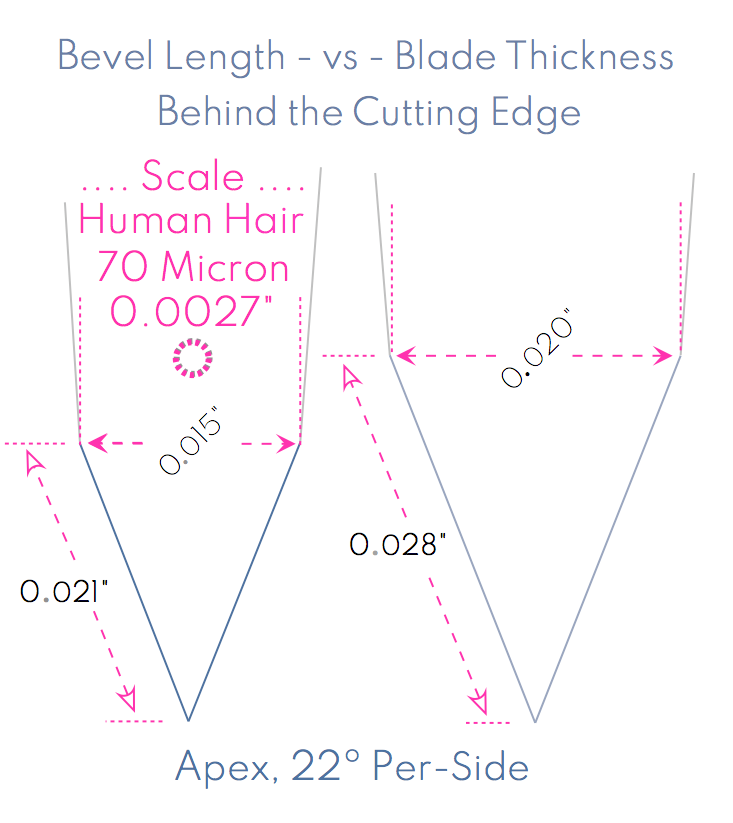

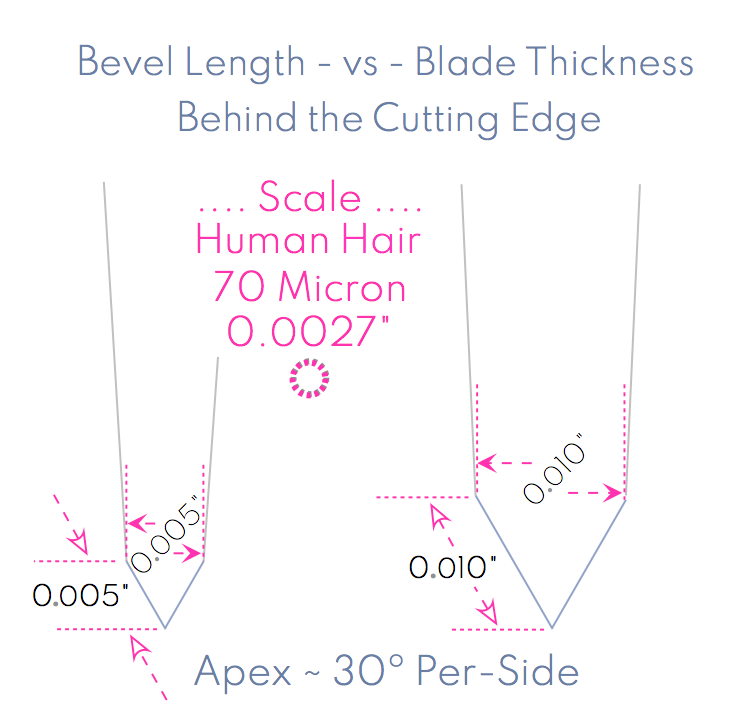

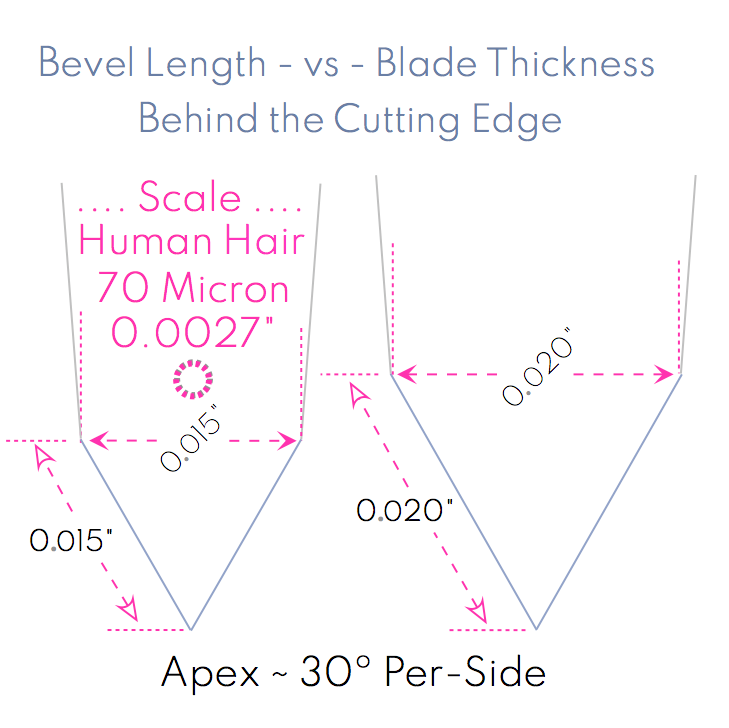

- A blade thickness increase of 0.005" behind the cutting edge ... doubles the perceived power necessary to cut high density vegetables.

( Copy paper is 0.004” )

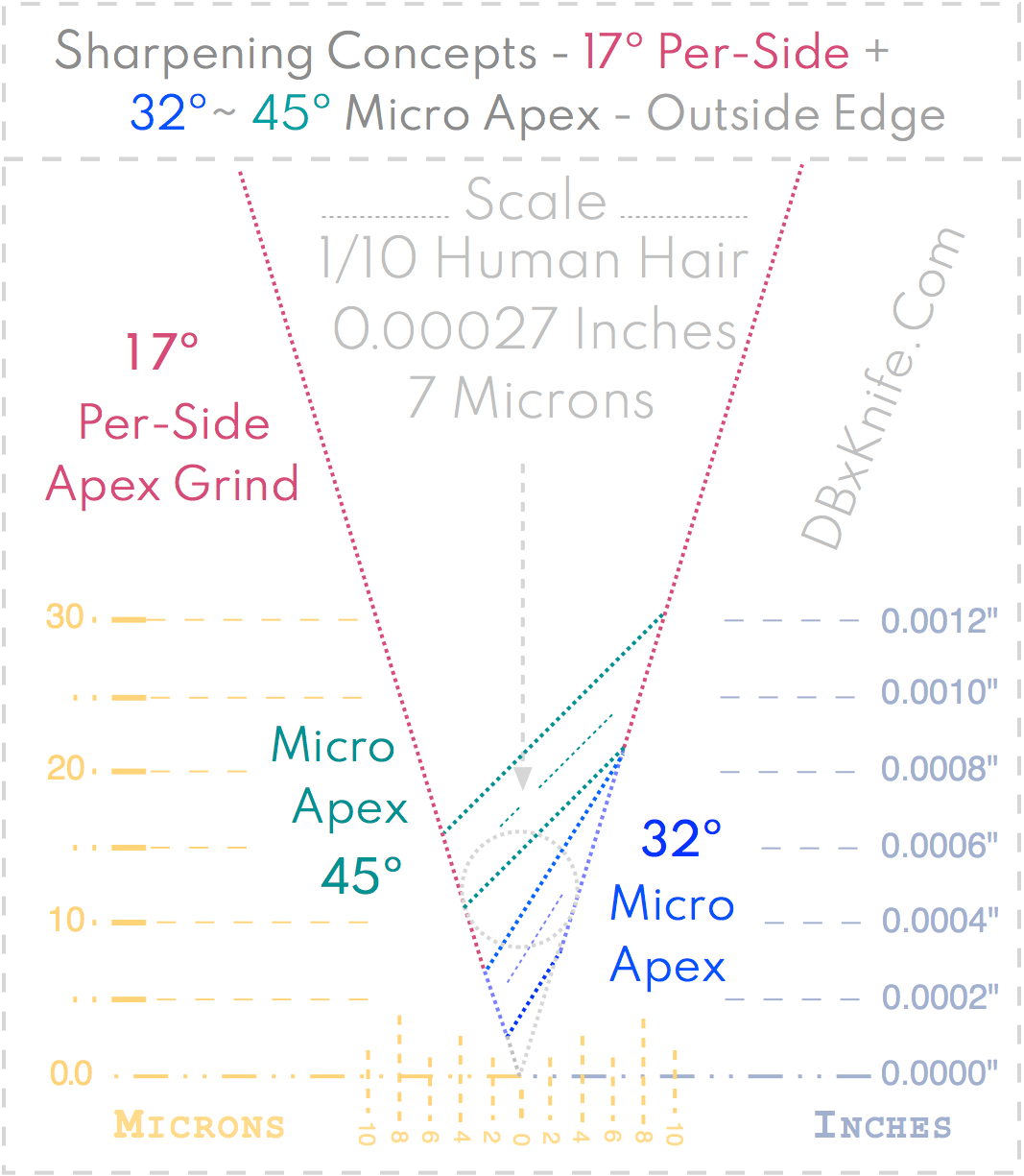

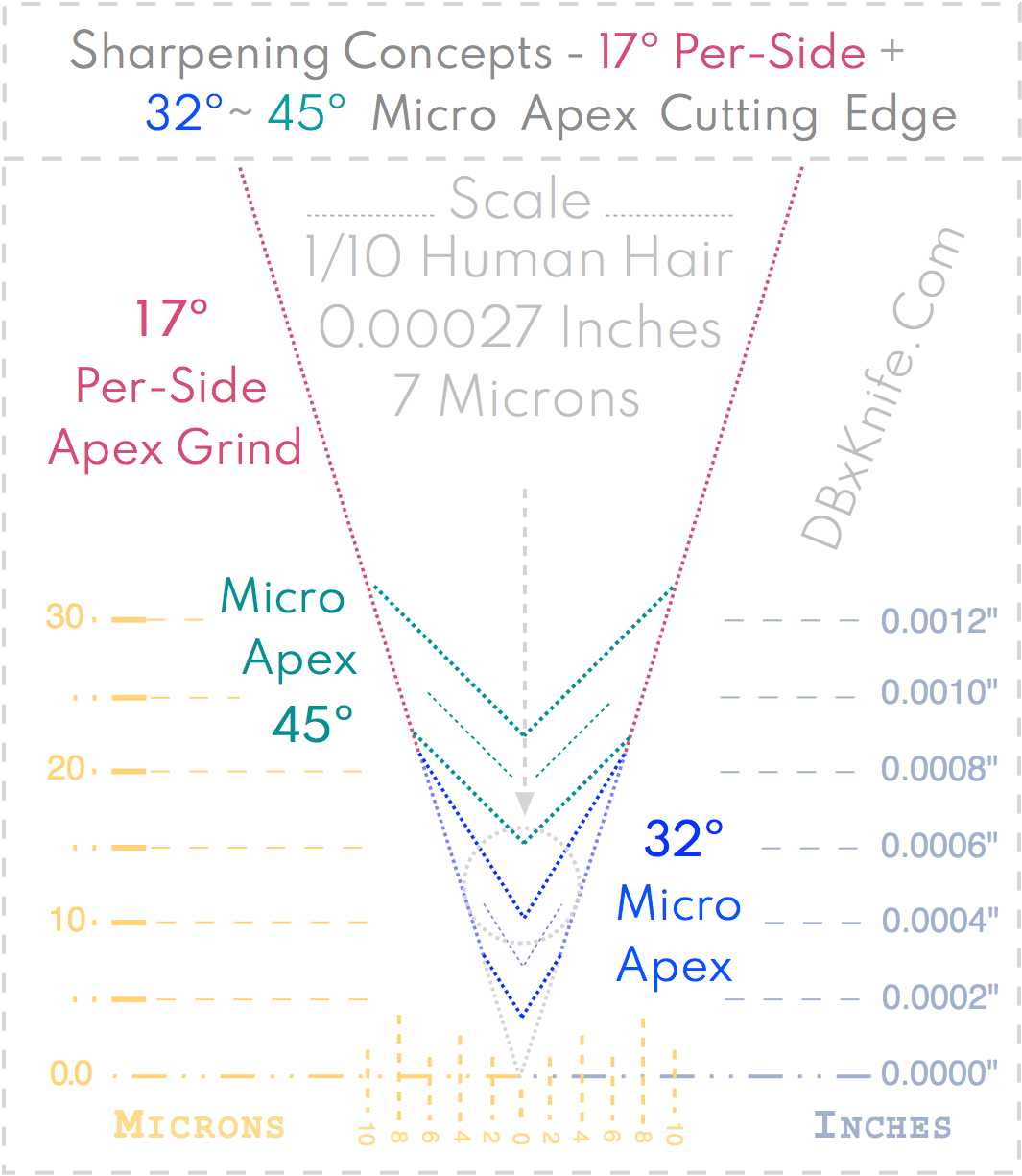

Micro-Apexing Concepts

Apex - Stability & Durability... Enhanced

Sharpening Tips . . .

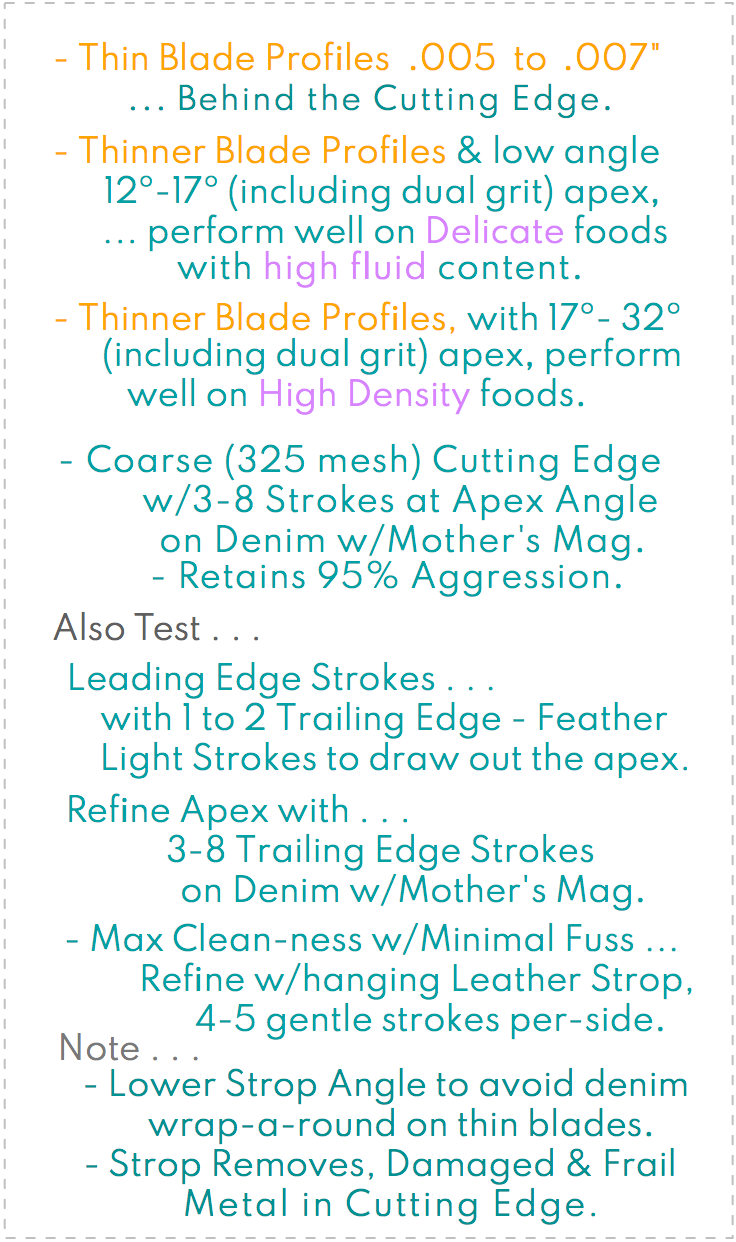

- Double bevel cutting edges with micro apex, chosen to limit edge rolling & chipping, yield the best performance.

- Combining a 17º thinning apex grind with a 32º to 45º micro apex grind, work well for culinary prep knifes.

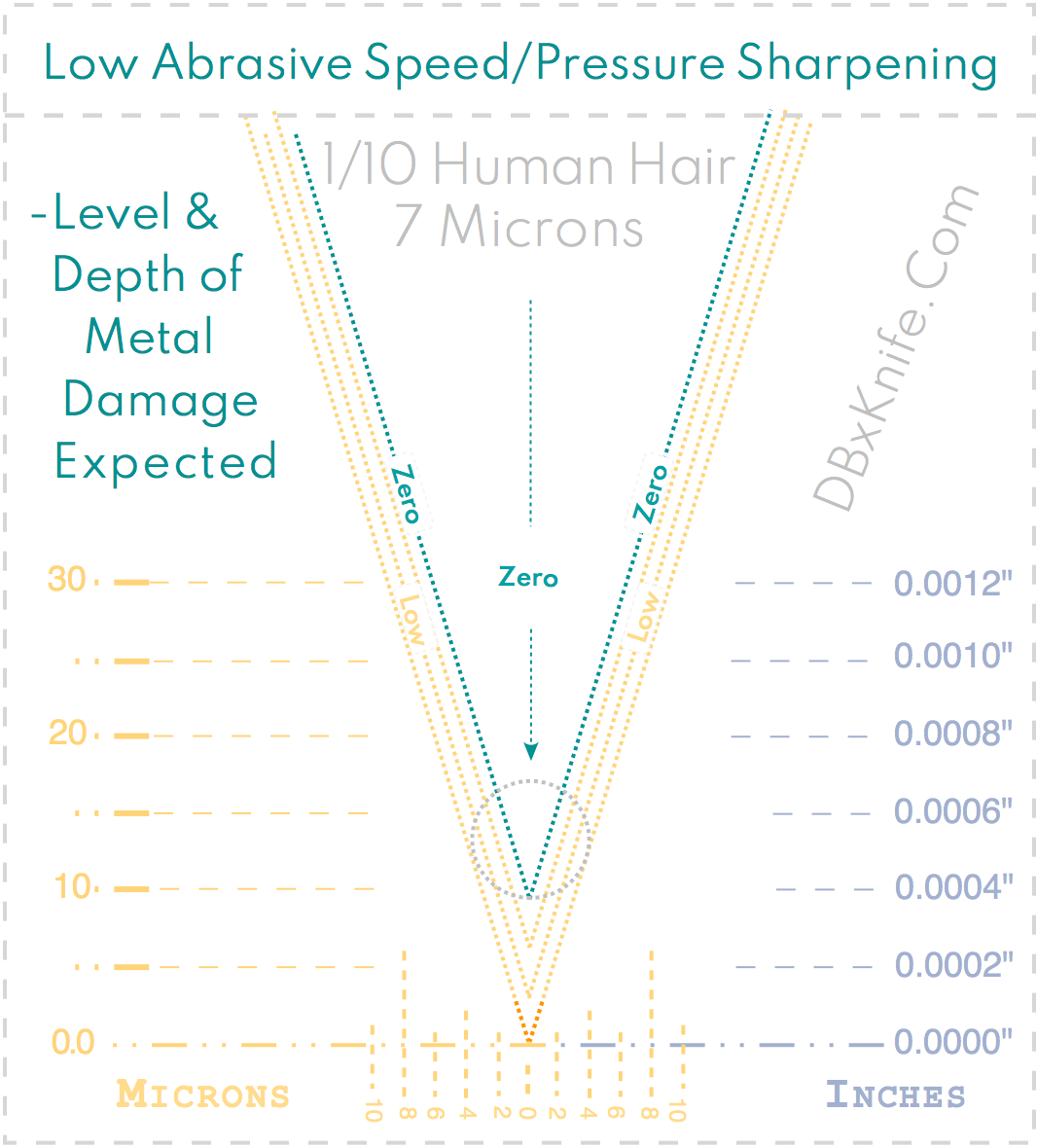

- Hand sharpening methods produce the most durable cutting edges.

- Ideally, only extremely small amounts of metal are removed in the process of sharpening thin knives.

- High-speed, automated sharpening systems significantly reduce cutting-edge durability.

- Razor sharp ( 12-15º) cutting edges are not necessary & often lack the strength to withstand cutting board contact.

Sharpening Tools & Info . . .

- Dual grit diamond sharpers are: inexpensive ($ 10~75), easy to maintain & use.

- Sharpening stones work, but require more maintenance than diamond sharpening plates.

- The consensus is 300 to 400 grit on the coarse side & 600 to 1000 grit on the fine side.

- Culinary knives ... 2 to 4 alternating light pressure leading edge strokes, 17º to 34º per side, then test.

- The more metal removed from the cutting edge, the thicker the blade becomes behind the cutting edge.

- Your goal is preserving the thinnest portion of the blade...

the real magic behind a high-performance knife.

Apex Surface Damage

Sharpen Methods - Compared

Automated Sharpening ...

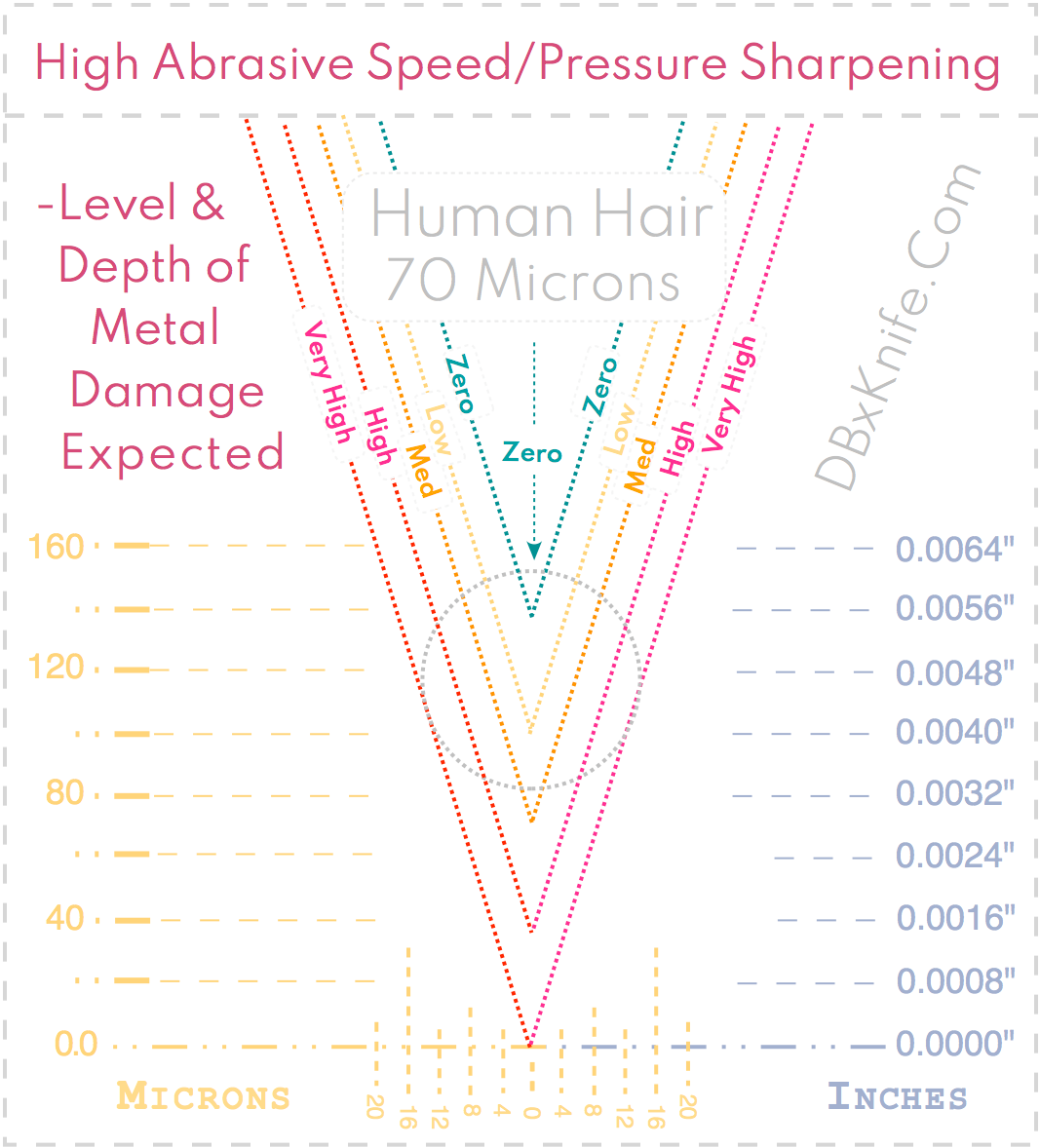

- High abrasive speed/pressure sharpening tools & systems often produce low durability cutting edges.

- These tools often grind an excessive volume of metal from the knife blade & shorten the practical life of a knife.

- They also suffer from diminished stability compared to hand-ground cutting edges.

- High abrasive speed sharpening systems may degrade knife steels by . . . 4 to 5+ HRC.

- Expected cutting-edge wear resistance can diminish by 20 to 25% or more.

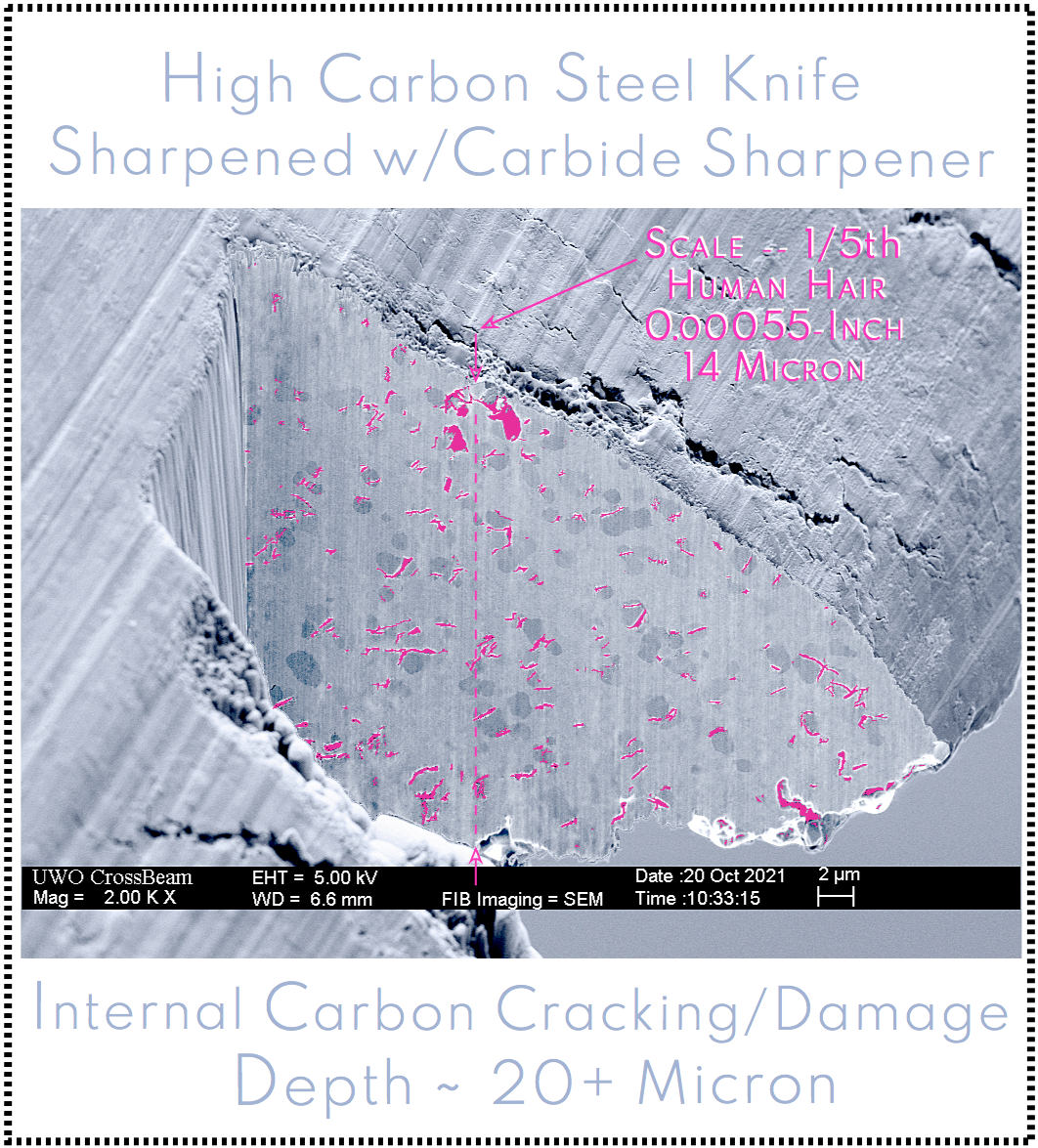

- Heat & stress-related carbon cracking likely accounts for another 25% reduction in cutting-edge durability.

- Performance testing reveals...

cutting force requirements may increase at 2x the rate of hand-sharpened knives.

Grinding Performance Away

- Grinding away the thinnest portion of the blade quickly deteriorates the cutting performance of your knife.

- Perfecting 100% vs. 99.99% of the cutting edge, often entails removing 4x more metal.

- Thickness behind the cutting edge then also increases at 4x the rate.

- As blade thickness behind the cutting edge increases, performance deteriorates quickly, even on razor-sharp culinary knives.

- Blades, thicker behind the cutting edge, require more power input, especially when cutting high-density foods.

- Knife blades can be thinned to recover cutting performance, but this is a time & resource-intensive or expensive process.

- Most often,

these knives are discarded,

a total loss for the consumer & a big win for the retailers.

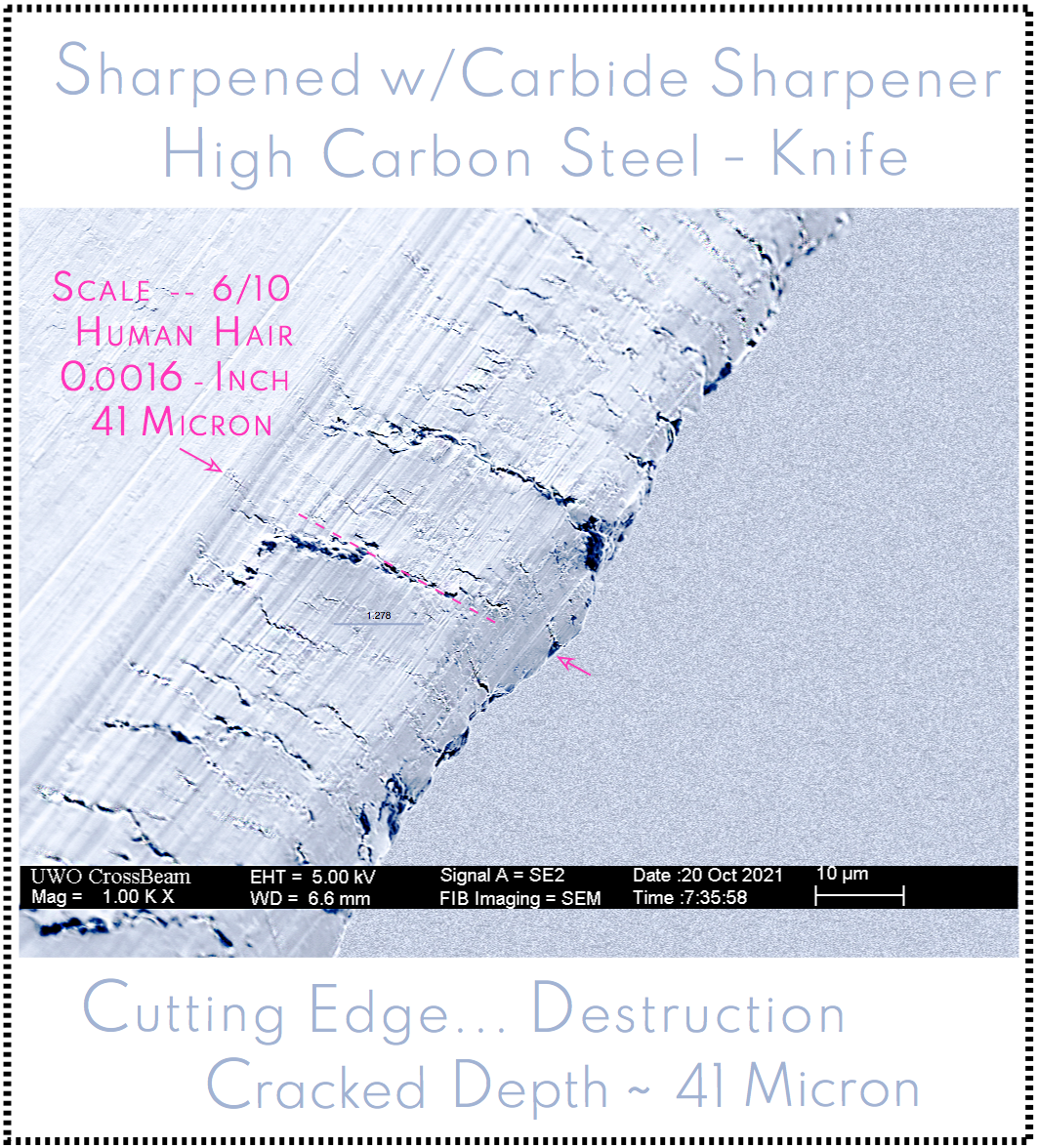

Cutting Edge Destruction

- by Carbide

Sharpeners -

Knife Blade Loss ...

- 200 Microns of blade height is lost in the sharpening process.

- Another 50 Microns is lost to remove the remaining substantially damaged steel.

- Blade wear, plus repair losses, equates to 250 Microns ( 0.010" Inch).

- Well-maintained knife blade height loss per sharpening event = 25 Microns (0.001" Inch).

- Damage to extremely thin knife blades may exceed 2,500 Microns (0.100" Inch).

- Carbide sharpeners diminish cutting performance & the useful life of a knife.

Cross-Section Micrograph

- Apex depicted after the pull-through carbide sharpener has deformed the cutting edge.

- Cracks & voids have formed amongst carbides in this high-carbon steel blade.

- Restoring cutting-edge stability would require grinding away damaged steel.

- Relative knife performance decline & knife blade wear rate are 10x more than normally expected.

- Knives can be thinned & resharpened to recover cutting performance.

Bevel Length ~ Blade Thickness

Shorter Bevels=Less Metal=Easy to Sharpen

Burr Removal & More Tips

Stropping . . .

- This is a process intended to capture & remove burrs created in the sharpening process.

- Strops are often made of leather, denim, or other relatively soft materials, usually embedded with an abrasive.

- Ideally, the burr is captured, folded under & quickly separated from the more stable metal in the cutting edge.

- I prefer a feather-light edge leading stroke using a 600 to 800 grit diamond plate to remove any significant burr.

- Extremely refined cutting edges often increase surface area in the apex & limit slicing aggression.

- A toothy cutting edge is often preferred by culinary cooks & chefs.

Additional Insights . . .

- Knife salespeople often select foods & materials to hide knife design issues.

- Soft, delicate & brittle foods are all selected to hide performance issues with thick knife blades & traditional handle geometry.

- Low angle ( 10º to 15º), razor-sharp cutting edges initially hide performance concerns with thicker knife blades.

- Microscopic, low-angle cutting edges deteriorate rapidly when they come in contact with bones, seeds and/or cutting boards.

- All knives get dull.

The best knife to own has a handle that fits your hand with a blade you can quickly & easily sharpen.

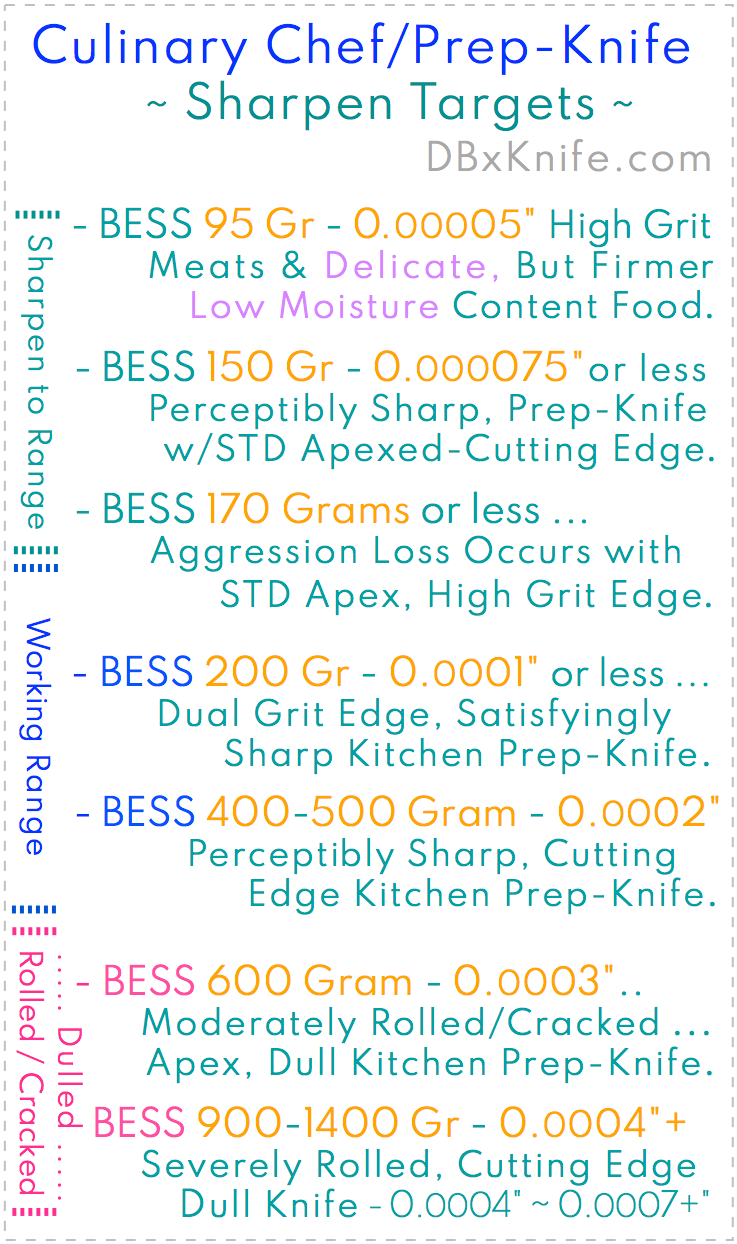

Chefs/Cooks Prep-Knives

Sharpening,

Info &

Tips,

My Notes