High-Endurance Cutting Edges

Challenges Revealed in High Magnification

Tough Cutting Edges . . .

- Apex photos & drawings are presented below with annotations to clarify some of the latest research currently shared online.

- Some of the most informative web sites I have found to date . . .

- ScienceOfSharp.com

( Sharpening Photos & Info.)

- www.youtube.com

/@HomeSliceSharpening. . .

( Dual-Grit Sharpening

Info & Video )

-Instagram.com/KnifeSteelNerds

( Knife Steel,

Info. & Videos )

- Optimization of knife steels & associated sharpening methods for best culinary cutting edges is an evolving science.

- These individuals have spent countless hours & resources to develop outstanding knife steels and sharpening methods.

- High magnification images of knife steels & cutting edges, created using various sharpening methods, are very revealing.

- People generously share their knowledge.

- Please:

Like,

Comment,

Support,

Share & Subscribe. . .

to support their generosity.

Knife - Apex Photos

Steel Damage - Cracks Highlighted

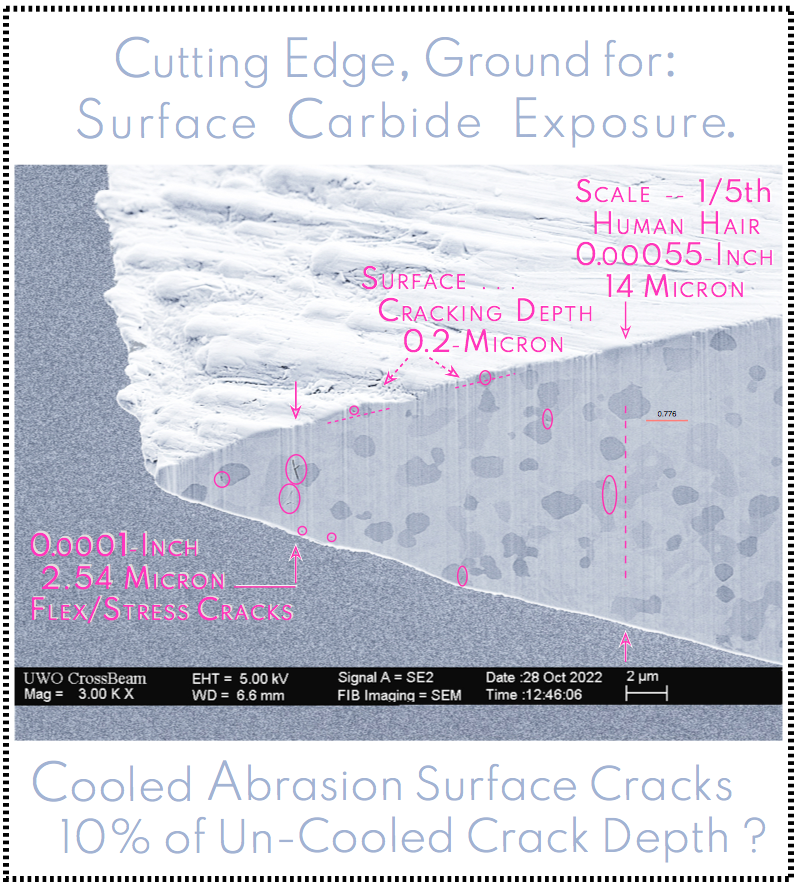

Innovative - Wet Slurry - Abrasive Sharpening

- Sharpened on a wet stone with a wet abrasive slurry.

- The slurry of abrasive grit & water, grinds away the softer elements of steel.

- Harder carbides populate the cutting-edge surface.

- A carbide-rich cutting edge reduces wear, improving edge retention.

- The wet slurry reduces abrasion-related blade surface heat buildup.

- Steel surface carbon cracking is minimal ( 0.3 Micron ).

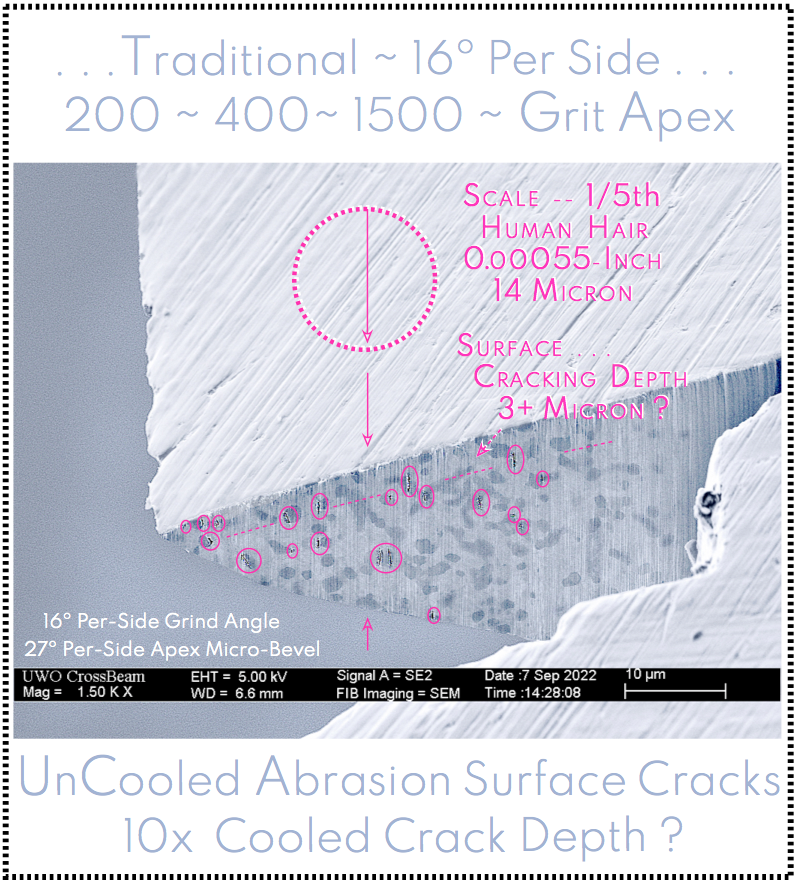

Classic - Apex Grind

Traditional, Dry-Hand ...

Sharpening Methods

- Sharpened with/on high-quality DMT diamond plates.

- This process yields minimal damage to the knife steel from abrasion-related heat & stress/flex.

- However, heat-related carbon cracking still seems to exist to a depth of 3 Microns.

- Additional cracking from steel flexing near the apex appears to be present at greater depths.

- Dry hand sharpening methods reduce steel damage by 90+% over many dry high-speed abrasive sharpening methods.

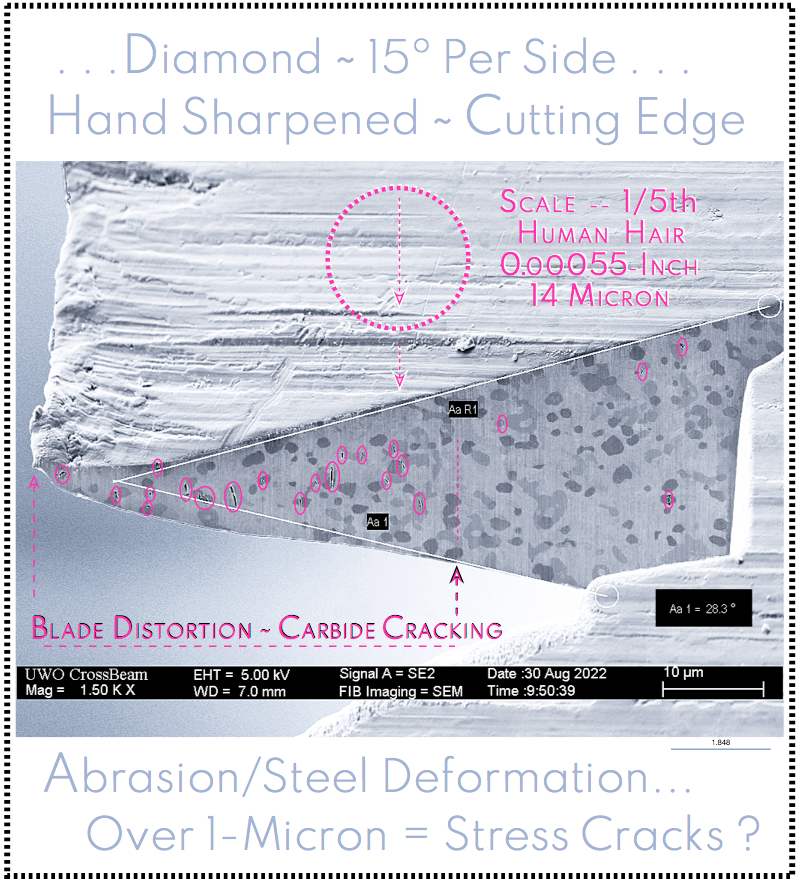

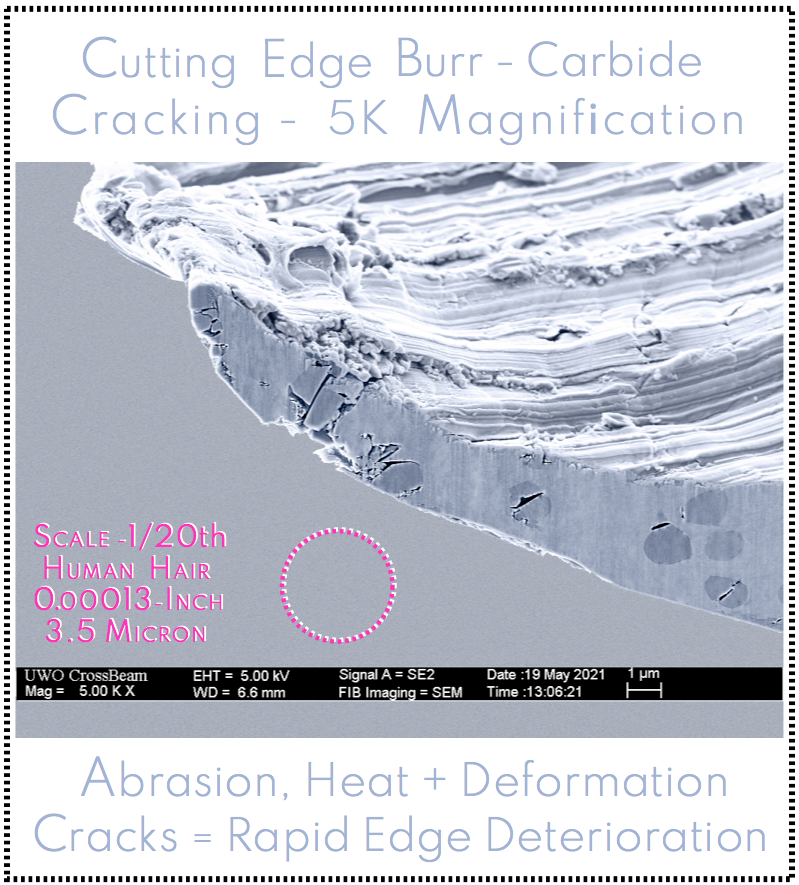

Cutting

Edge -

Burrs

Steel Distortion . . .

Increases Carbide Cracking

- Photo depicts a significant increase in carbon cracking at 0.5 Micron distortion levels . . .

- Increased cracking correlates with areas of steel distortion in the apex.

- Knife blade distortion exists in 17 Micron & thinner portions of cutting edge.

- Carbon cracking is prevalent in 15 Micron & thinner cross-sectional areas.

- Carbon cracking increases in 2.5 Micron & thinner flexed blade steel.

- Cracks deteriorate cutting-edge strength & durability.

- Steeling a cutting edge has the effect of distorting the apex over & over again.

- This process has

minimal short-term

value with

negative long-term

effects.

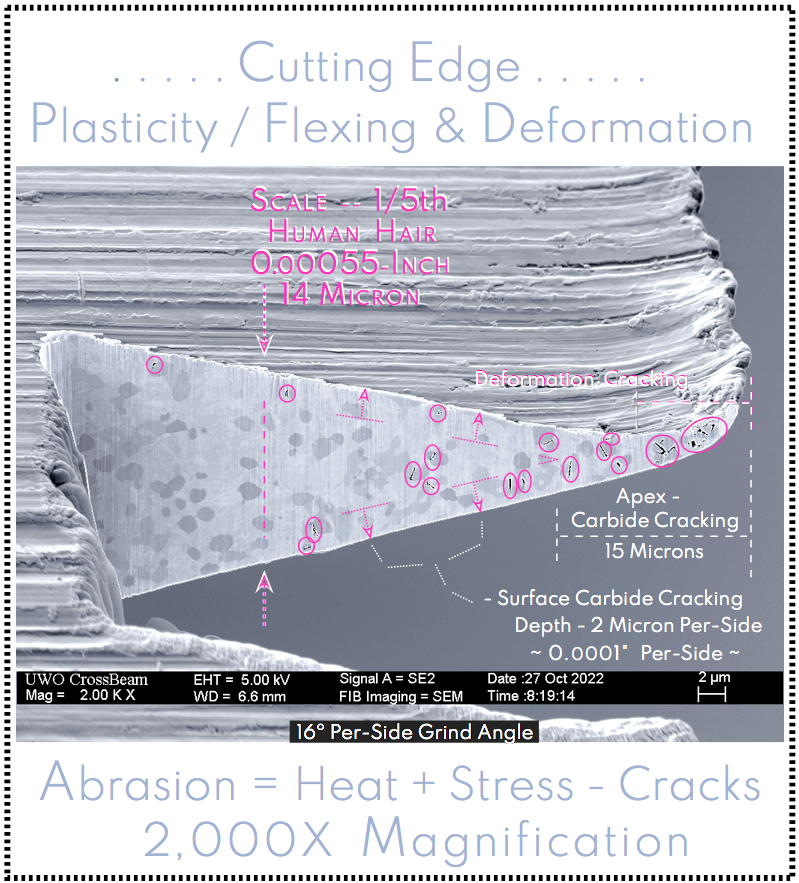

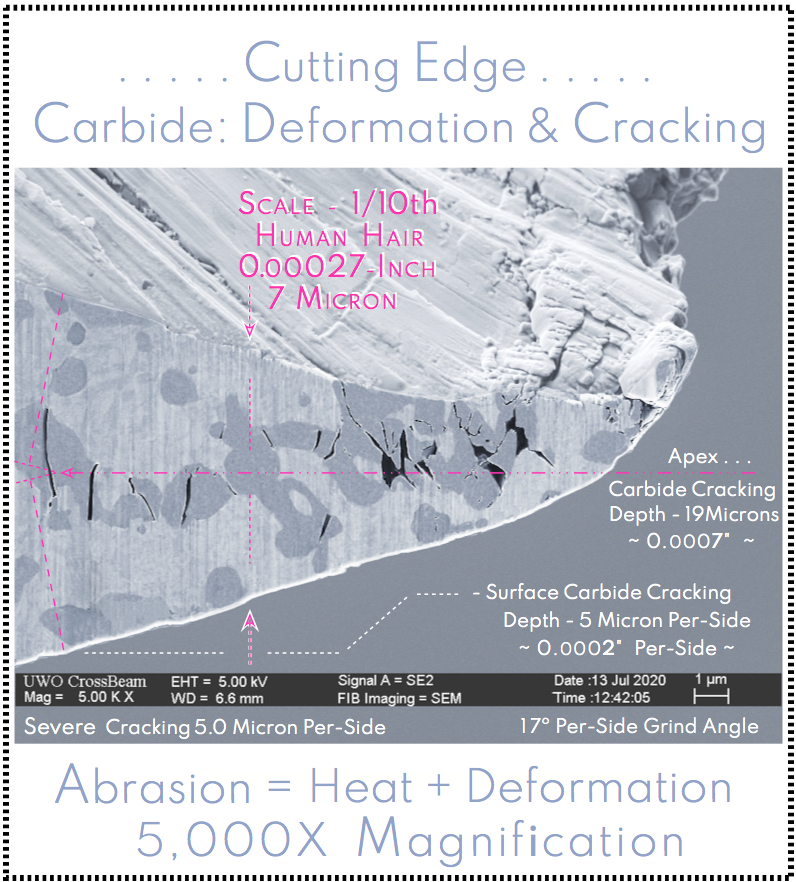

Apex - Surface

Cracking

Heat/Stress . . .

Carbide Cracking

- Photo depicts a hand sharpened with high-quality dry diamond plates.

- This dry process creates minimal heat & stress/flex in the knife steel.

- However, heat-related carbon cracking seems to exist to a depth of 2 Microns.

- Additional cracking from steel flexing near the apex seems to exist at 4 Micron.

- Increased levels of carbon cracking are visible in the deformed portion of the apex.

- Low angle small diameter cutting edges often chip out and/or roll over with minimal use.

- Micrographs seem to confirm, cutting-edges with radiuses below 2 Microns have stability issues.

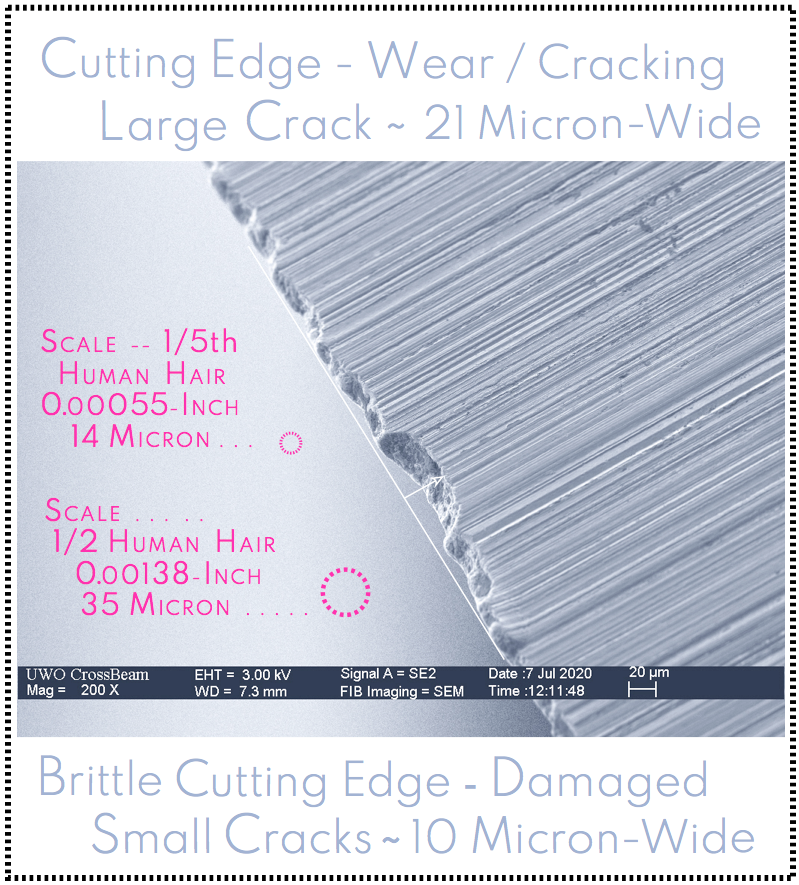

Knife Burr - Cracking

High Carbon Knife Steel

Apex/Burr Distortion

- Close examination reveals widespread cracking in the cutting edge.

- Cracks are visible on the surface & also revealed in the cross-section.

- Cutting edges, with cross-sectional areas of knife steel, less than 2 Micron, often roll over &/or chip out.

- The cutting edge depicted is likely hand sharpened on diamond plates, yielding relatively low levels of carbon cracking.

- High abrasive speed/pressure sharpening systems will yield more heat-related steel deterioration.

- Abrasion related heat/knife steel testing reveals 4 to 5 HRC point reductions.

- Wear resistance reduction calculation is a 5% per-point loss of HRC.

Hi-Magnification - Apex Cracking

Carbon Clumping &

Carbide Cracking...

- This image reveals severe carbon cracking across large carbon structures.

- With minimal use, the cutting edge will likely chip out, yielding a cutting edge radius of 3 Microns.

- The cutting edge depicted in this micrograph would yield razor sharp test results.

- Cutting edge durability would be less than ideal.

- Ideally, knife steel is balanced to provide hardness for long wear & toughness to avoid chipping out.

- The ideal balance depends upon user skill levels & foods they are cutting.

Micro - Chipped Apex

High Carbon Steel

Cracked/Chipped Apex

- This micrograph depicts a knife steel too hard for the intended use.

- Ideally, we trade off a bit of hardness for toughness.

- A 32º micro apex grind will increase apex stability & cutting performance.

- 32º plus apex grinds also perform well on softer knife steels, which often roll over.

- Stropping a 17º apex can easily yield a 25º to 30º micro apex.

- Avoiding heat build-up in knife steels during the sharpening process increases the durability of a cutting edge.

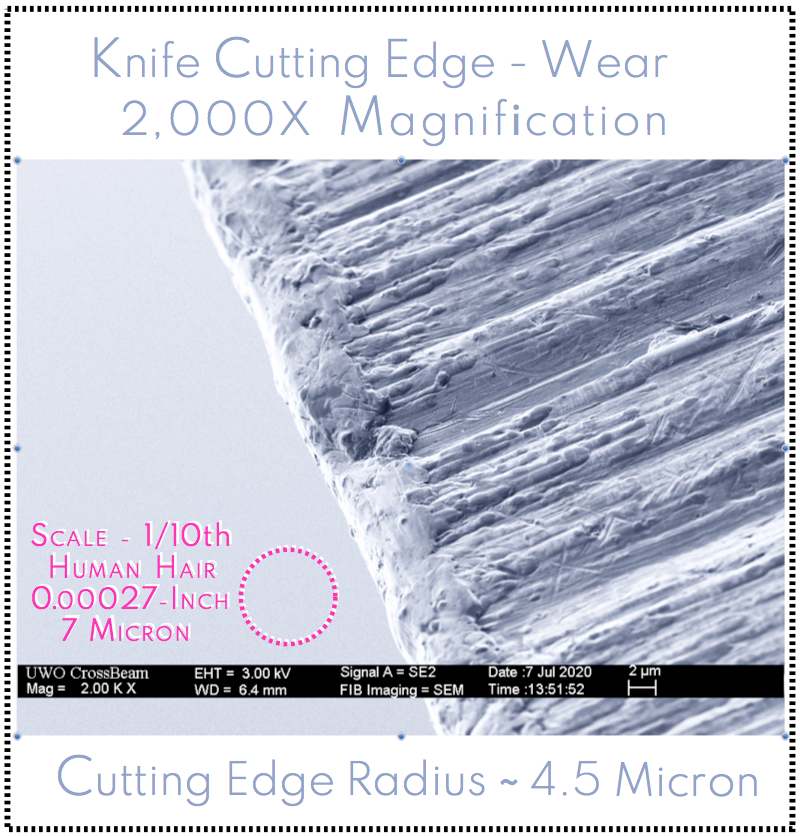

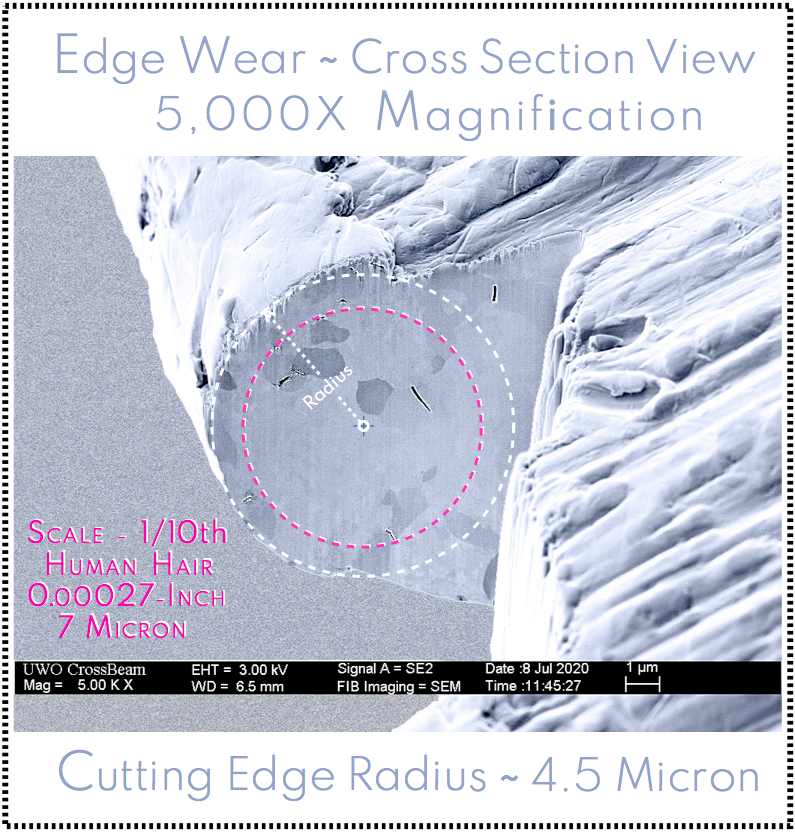

Knife Blades - Apex Wear

High-Endurance Cutting Edge

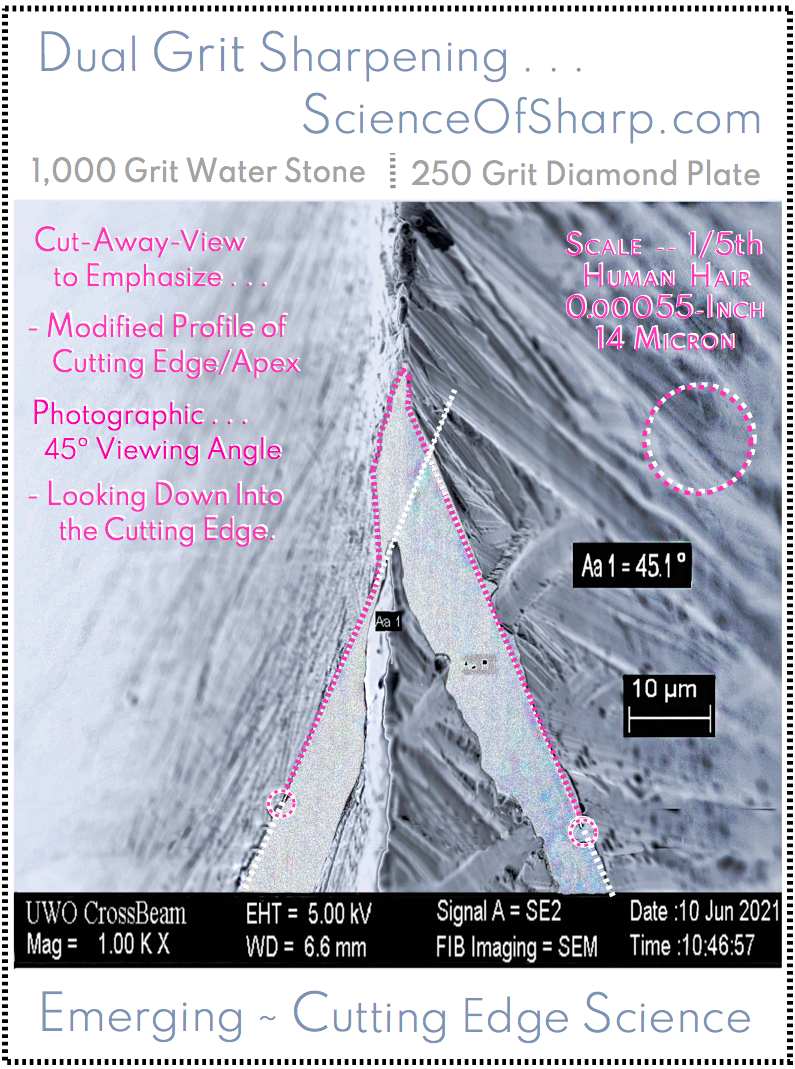

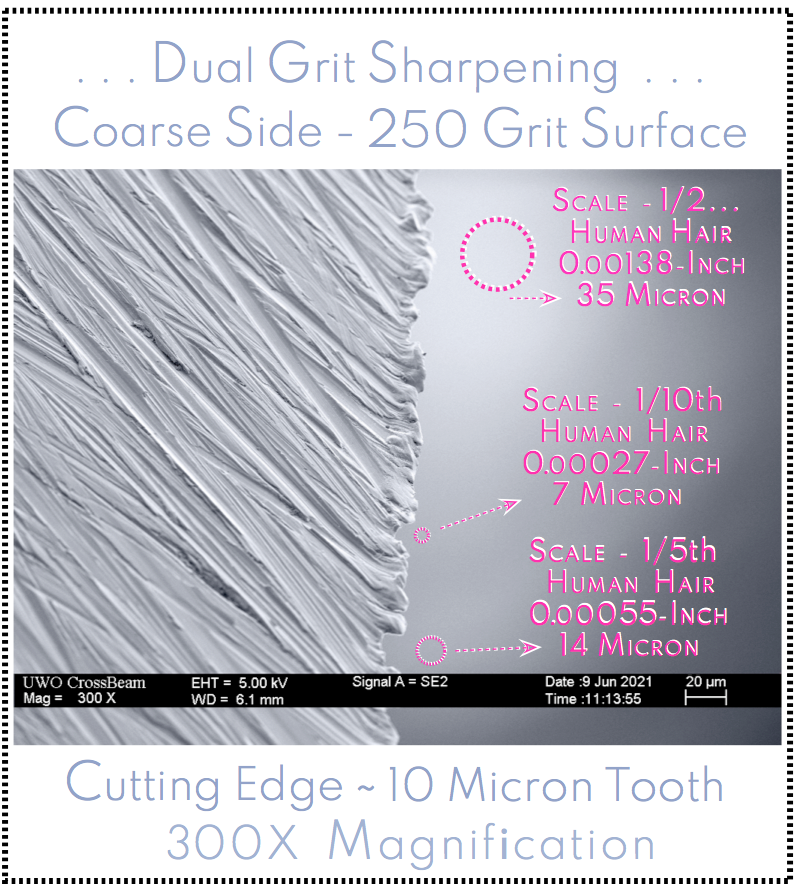

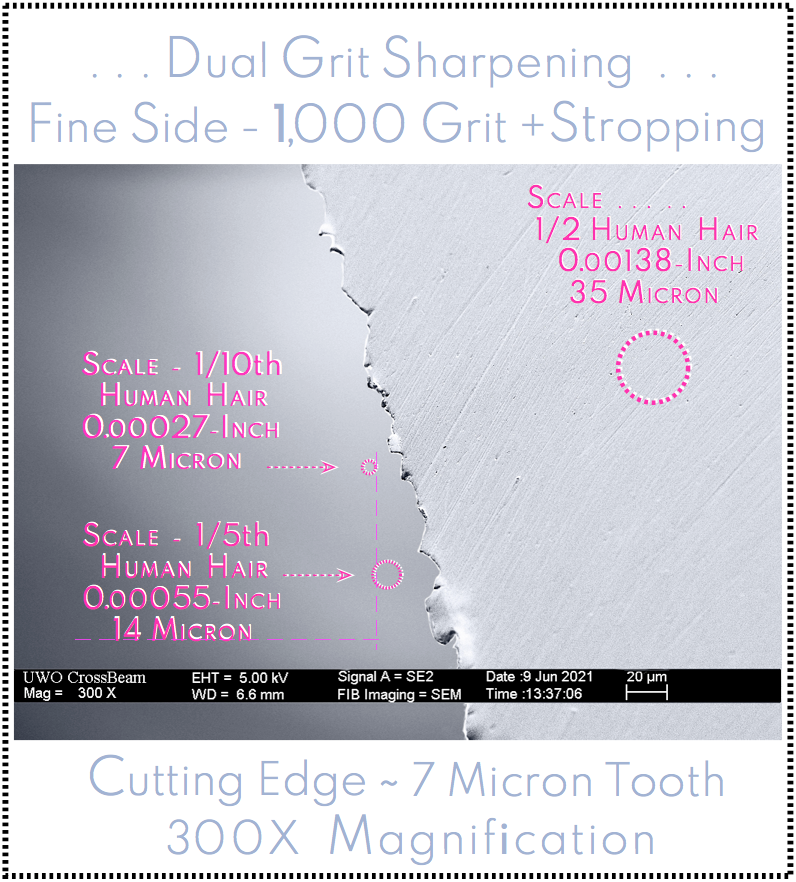

Dual Grit Sharpening,

High Performance

Cross-Section, Perspective

High-Magnification Cutting Edge View

Dual Grit Cutting Edge

- Cross-sectional view along the cutting edge/apex of a dual-grit sharpened knife blade before stropping.

- A burr is formed when steel cannot withstand the pressure necessary to abrade/grind it away.

- This image reveals a relatively large burr.

- This is metal forced outside the triangle... of the expected sharpening angles.

- A smaller burr is attached to the larger burr at the apex.

- This cutting edge was created using a dual grit sharpening method with edge trailing strokes.

- A 250-grit diamond plate and a 1,000-grit water stone were used to create this cutting edge.

Dual Grit - Apex Photos

Course & Fine - Apex Side Views

Higher Abrasive Speeds

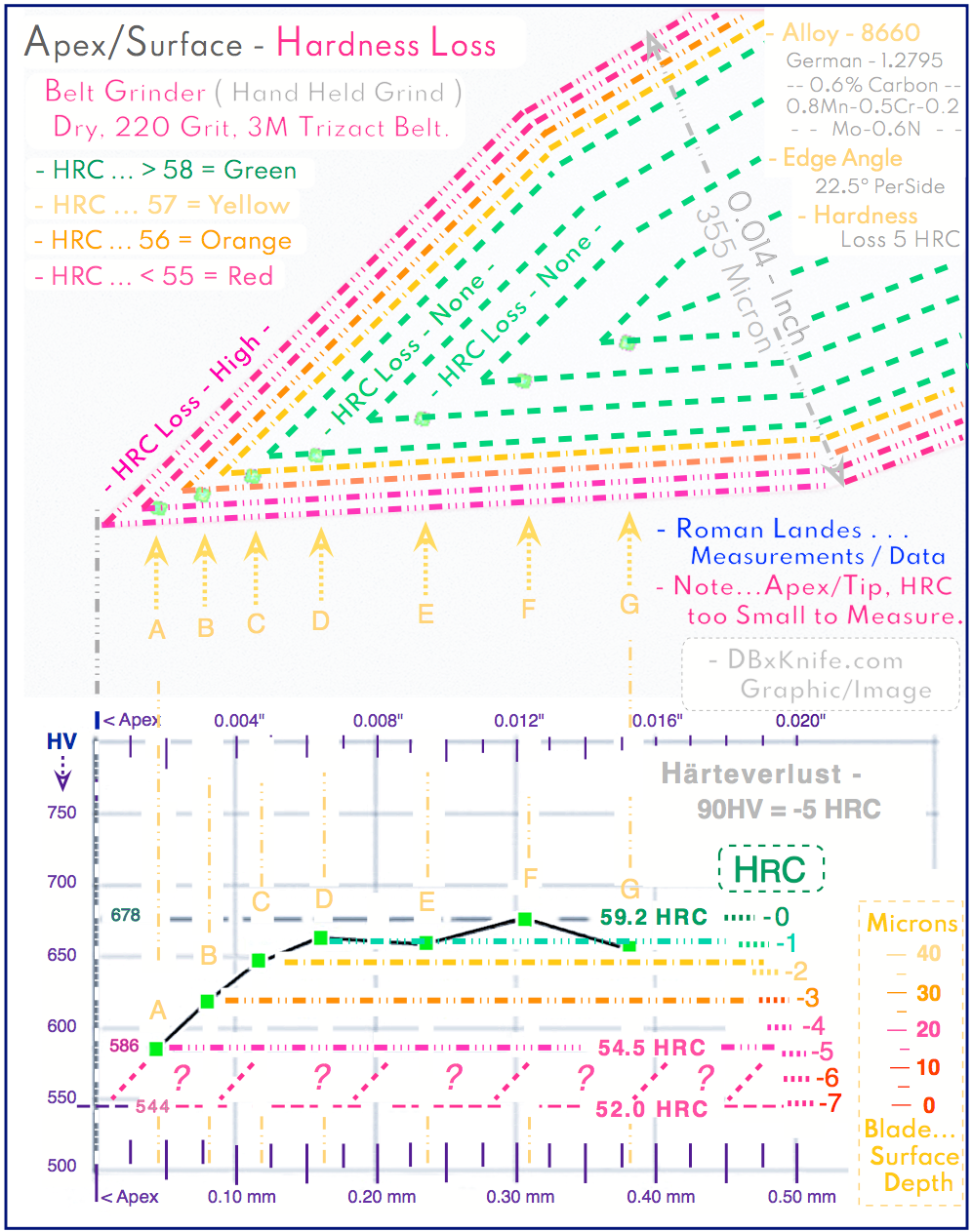

Test Data ~ Thoughts & Comparisons

High-Speed Sharpening

- Test data reveals significant HRC reduction in the cutting edge sharpened with high-speed abrasives.

- HRC deterioration depth: 100 Micron (0.004") behind the apex ... 38 Micron (0.0015") per side ... in this example.

- 90+% of this damage is avoidable using cooled and/or low surface speed/pressure abrasives.

- High-quality knife steel cutting edge durability is often reduced to that expected of low-quality knife steel.

- Mass-produced knives are often sharpened with high surface speed abrasives.

- These sharpening systems produce incredibly sharp, reduced durability cutting edges.

- Wet/cooled & lower speed/pressure sharpening processes reduce heat & improve HRC retention in the cutting edge.

- Resharpening a knife on a diamond plate or wet stone several times, often increases cutting-edge durability.

- This test data & diagram correlates well with my personal research & other test data shared on the internet.

Cutting Edge- HRC Issues

High Abrasive Speeds = High HRC Loss